But if you're utilizing HP 3D High Reusability TPA allowed by Evonik3, then the finished items will certainly be flexible, light-weight get rid of enhanced rebound resilience. The only limitation actually is the ingenuity of your developers and, obviously, your certain layout demands. 3D printing works by converting a 3D version into a set of computer-generated instructions to incrementally develop a part layer by layer. A lot of 3D printing innovations utilize this same standard facility to produce 3D published products. It's a fun time to be in the industry, as additional products advancements and process controls advance to additionally automate as well as excellent 3D printing for use in thousands extra applications. Tooling is needed in a range of production procedures, from shed wax tooling for investment spreading to steel tooling for shot molding.

Unlike machining, which commonly calls for a hands-on designer to implement the lines of code required to machine a part, 3D printing software application automates the production of line by line info to construct a part one layer at a time. Tipping beyond design methods for these standard manufacturing procedures directly leads to raised expense as well as labor. It is important to consider these factors due to the fact that how a part is oriented figures out where assistances are included-- or required-- within the develop. Supports are a big factor for 3D printing, and also can affect product surface and precision of a 3D published part. Comparable to CNC machining, positioning aspects into the end result of surfaces and also information on a 3D printed component. Since 3D printing develops one 2-D layer each time, the specific lines appear as ribbed surface areas on components.

Support & Solutions

Although an optimal scaffold will make up all these factors, obstacles still exist with biomaterial selection as well as 3D form specificity. Each biomaterial has certain product and also mechanical residential properties, processing approaches, chemical residential properties, cell-material communications, as well as FDA authorization. Typical manufacture methods to produce porosity as well as a series of pores size are gas frothing, solvent casting with fragment leaching, freeze-drying, and eletrospinning. While the microarchitecture in these methods is well-controlled as well as understood, the capability to regulate macroarchitecture with these techniques is limited to 3D forms and also geometries established by molds and also manual handling. The ability to include inner style or curved networks is additionally limited when utilizing these approaches.

3D Printers Were Never Going To ‘Save’ Manufacturing, But Here’s How They’re Quickly Becoming An Industry 4.0 Staple - Forbes

3D Printers Were Never Going To ‘Save’ Manufacturing, But Here’s How They’re Quickly Becoming An Industry 4.0 Staple.

Posted: Mon, 15 May 2023 07:00:00 GMT [source]

Column cladding SL Rasch GmbH SL Rasch GmbH counts on 3D printing for the visualization of architectural jobs. HSS Product Network-- Evidence of Principle HDPE Along With Fraunhofer IPA we have certified the polymer HDPE for additive manufacturing within our HSS Product Network. HSS Product Network-- Proof of Principle Iglidur A brand-new evidence of concept withing the HSS Product Network evidence effective 3D printing of igildur ® i3 PL via HSS. 3D printing for enhanced electrical motors Aiona Cast has actually filed a patent application to substantially maximize electrical motors. The only exemptions were exceptionally high-priced tailored unique designs for leading athletes.

Metal

Right here are a few of the areas where 3D print technique is playing an important part to drive technology and also growth. Also then, thermoplastics are among one of the most prominent materials for 3D printing innovations today. Acrylonitrile Butadiene Styrene, Polylactic Acid, PolyCarbonate, as well as Polyvinyl Alcohol are some of one of the most common options throughout various industries because of their adaptability and also suitable qualities.

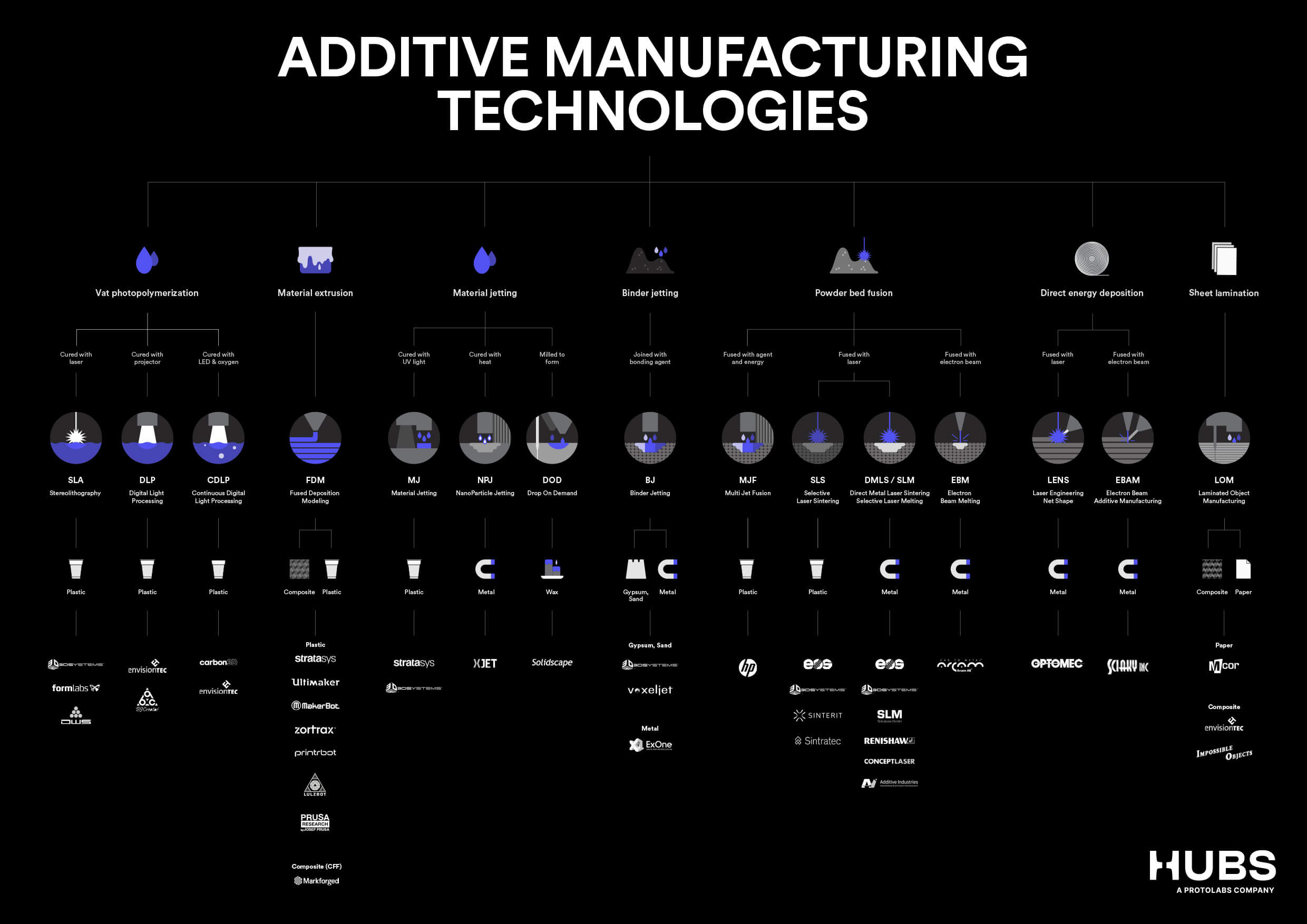

Which innovations are presently made use of in 3D printing?

- Material Extrusion.Fused Deposition

- Modeling( FDM) 3D Bioprinting.Construction 3D Printing.Vat Polymerization.Stereolithography (SHANTY TOWN)

- Digital Light Processing( DLP) Fluid Crystal Show( LCD)

In November 2022, researchers at the College of Maine Advanced Structures and Composites Facility completed a 600 square feet home made up of modular sections published from timber byproducts. In D Concrete Printing began at Loughborough College, UK, headed by Richard Buswell as well as colleagues to extend the teams prior research as well as want to commercial applications relocating from a gantry based innovation to an industrial robotic. • Titan Robotics-- Titan Robotics manufactures Atlas as well as Hyperion huge format 3D printers in the US. The Atlas has a 5 cubic meter construct quantity while the Hyperion's quantity is over 35 cubic meters, among the biggest in the world. 3. Begin with basic 3D layouts as well thereyouhaveit3d as progress to much more complicated ones as you get experience.

The resulting scaffolds have actually the desired villi-shaped pillars and high porosity as well as interconnectivity. Bronze sculpture developed by 3D spreading Using 3D printing, we develop a 2.2 metre high plastic investment spreading pattern cast in bronze by the London Casting Business. 3D printing for the pump sector Our Binder Jetting Innovation is an outstanding alternative to traditional production. Prototyping for the auto market A rather uncommon project emphasizes the capabilities of additive production innovation also beyond its classic areas of application. 3D printing for product as well as interior developers 3D printed design items open up brand-new possibilities for product designers, interior designers as well as musicians to display their job and layout remedies. Taking 3D printing to the following level for architects as well as element home builders Binder Jetting" 3D printing is ideal for large-format and highly complicated building projects. 3D printing for the whole BIM process chain.

- The integration of SFF technologies with patient-specific clinical imaging data enables the aseptic manufacturing of cells design grafts that match specifically to a person's shapes can be produced by.

- It is essentially mould-free shot molding of last structures, making it feasible to produce one-of-a-kind, one person at once clinical device.

- Yet when those difficulties are overcome-- or alleviated-- rate of interest in various 3D printing materials is high.

In vitro research studies with bovine chondrocytes for articular cartilage material cells design, bone tissue engineering, monocytic cells from the RAW 264.7 cell line, human osteoblasts, C2C12 pre-myoblastic cell line, and bone marrow stromal cells. In vivo studies have been carried out with bunny calvarial bone, rabbit shin bone as well as porcine maxillary bone, rat femoral defects, mouse femoral defects, and also rabbit femoral bone. This trouble was addressed by a sensible, indirect 3DP protocol, where mold and mildews are published and the last products are cast right into the mold and mildew tooth cavity.